What is Prototyping Machining?

Prototyping Machining refers to the process of converting design drawings into physical models through CNC machining, 3D printing, turning, milling and other technologies. This processing method is mainly used to manufacture product prototypes to verify the feasibility, functionality and appearance of the design, and is usually suitable for the early stages of product development. As an efficient and precise manufacturing method, Prototyping Machining can shorten the product development cycle and reduce development costs.

MINGNON focuses on providing Custom Prototyping Services, combining advanced technology and experience to customize high-quality prototype processing services for customers, which are widely used in multiple industries.

Features of Prototyping Machining

Prototyping Machining can achieve a machining accuracy of ±0.001mm. High precision enables the prototype to fully restore every detail in the design drawing, especially in the manufacture of complex structures and tiny components. At the same time, Rapid CNC Prototyping also provides extremely high machining efficiency. For example, in the manufacturing process of a standard part prototype, the delivery time from design to finished product can be shortened to 3-7 working days, which saves up to 50%-70% of time compared with traditional mold manufacturing.

In terms of material selection, Prototyping Machining also shows great flexibility. A variety of materials can be processed, including aluminum (such as 6061-T6, 7075), stainless steel (such as 304, 316L), brass, POM, ABS, PC and other plastic materials, as well as high-performance composite materials.

This material diversity makes its application range extremely wide, from aerospace and automotive manufacturing to consumer electronics and medical devices. For example, in the field of consumer electronics, the shell prototype made by Prototyping Machining can simulate the texture and strength of the real product and meet customers' demand for high-quality appearance.

This processing method allows small-batch customization and usually supports production needs of one to 500 pieces. It is especially suitable for small-batch verification in the research and development stage of new products. In terms of cost, since there is no need to open a mold, its initial investment is usually 30%-60% lower than mold manufacturing.

Application fields of Prototyping Machining

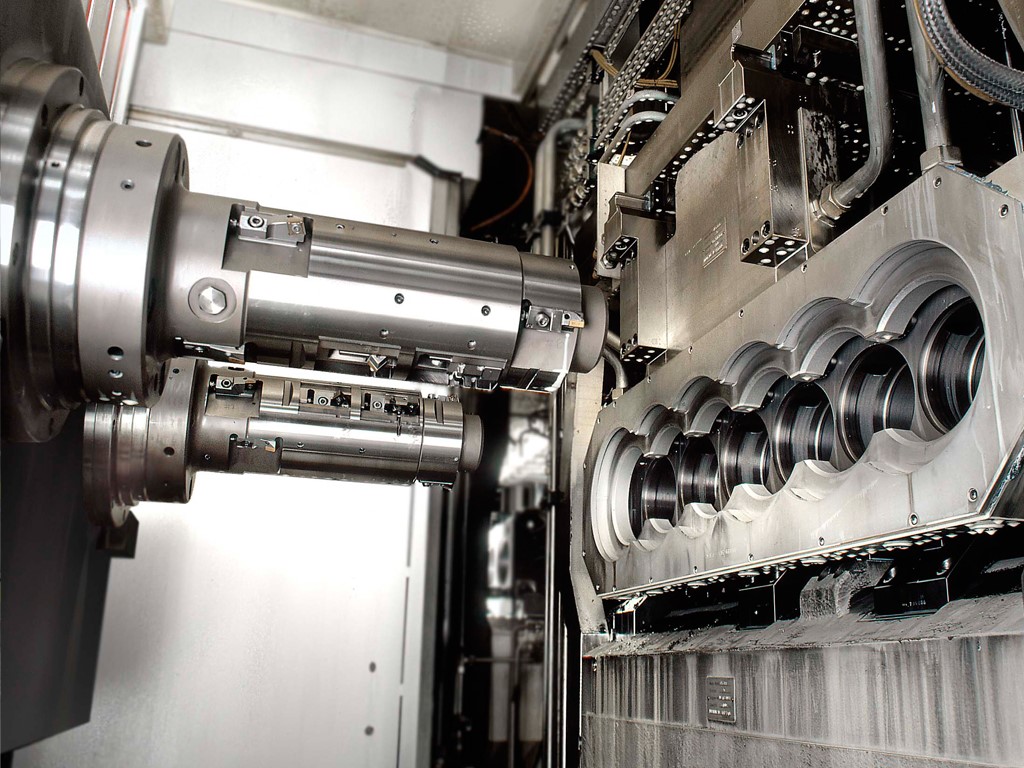

Prototyping Machining is widely used in many industries and is an important means of rapid product verification and development. In the field of consumer electronics, it can manufacture prototypes of housings and parts of devices such as mobile phones and smart watches to simulate the appearance and functions of real products; in the automotive industry, it is used for the development of engine components, body structural parts, etc. to accelerate R&D iterations; in the aerospace field, it can process high-precision turbine blades and cabin structural parts to meet complex geometry and performance requirements. Applications in the field of medical equipment include surgical tools, implant prototypes, etc., to assist preoperative simulation. In the industrial equipment, home appliance manufacturing and luxury goods industries, Prototyping Machining can quickly develop pump housings, home appliance parts and high-end jewelry models, providing flexible and efficient support for innovative designs.

FAQ

Q: What documents do you need to provide when choosing Prototyping Machining?

A: You need to provide detailed CAD drawings (such as STP, IGS files) and specific material and surface treatment requirements.

Q: How long is the manufacturing cycle of the prototype?

A: The manufacturing cycle is usually 3-10 days, depending on the complexity of the design and the material selection.

Q: Can small batch production be carried out?

A: Yes, Prototyping Machining supports flexible small batch production, which is suitable for market testing and design verification.

Q: Can the design be modified during the processing?

A: Adjustments can be made before processing or in phased production, but additional communication of modification requirements and costs is required.

Q: What surface treatments are available?

A: Supports surface treatments such as anodizing, electroplating, spraying, and polishing to improve the appearance and durability of the product.

Q: How to ensure processing accuracy?

A: Through advanced CNC equipment and strict quality inspection processes, ensure that the processing accuracy meets the requirements of the drawings.

Q: Can the prototype be used directly for functional testing?

A: Most prototypes can be used directly for functional testing, but it is necessary to confirm whether the material meets the specific test requirements.

Q: Is there a large loss of material during processing?

A: The loss is small. Usually, process requirements are considered during design to optimize material utilization.

Q: How to transport the prototype after processing?

A: Professional packaging is used to ensure the safety of the prototype during transportation to avoid damage or deformation.

Q: How to contact MINGNON for customized services?

A: Welcome to contact us by email or phone, we will provide professional solutions according to your needs.

As a professional prototype processing manufacturer, MINGNON is committed to providing customers with efficient and high-quality Custom Prototyping Services. Our advanced equipment and technical team can meet your various needs in product development. If you need customized services, please feel free to contact us!