MINGNON is a provider of a variety of high-precision services, including CNC milling, prototype machining, five-axis CNC machining, etc. Our technology covers a wide range of fields and can meet the personalized needs of customers. We also provide die casting and assembly services to ensure that each product meets the most stringent quality standards. With advanced equipment and an experienced team, MINGNON is committed to providing customers with excellent manufacturing solutions.

MINGNON CNC machining services include CNC Milling, Prototyping Machining, 5 Axis CNC Machining, Die casting, Assembly Service and other processing processes. Suitable for various industry needs. The machining accuracy we provide can reach ±0.001mm, and the materials processed include aluminum, steel, stainless steel, titanium alloy, etc., which are widely used in aviation, automobile, medical and other fields.

MINGNO is a manufacturer specializing in custom CNC milling parts processing. The company is committed to providing customers with high-precision, high-quality CNC milling services to meet the needs of different industries such as electronic equipment housings, connectors, and electronic devices.

MINGNON focuses on providing Custom Prototyping Services, combining advanced technology and experience to customize high-quality prototype processing services for customers, which are widely used in multiple industries.

5 Axis CNC Machining is a high-end precision machining technology that can simultaneously control the movement of five axes during machining. This technology allows for one-time efficient machining of workpieces with complex geometries, especially for parts with complex curved surfaces and multi-angle features. Compared with traditional three-axis machining, five-axis machining can avoid multiple clampings and improve machining efficiency and precision. MINGNON has a professional Evermi five-axis five-link 850 machine, which performs particularly well in machining complex parts. Its high speed and high precision make it an ideal choice for precision manufacturing.

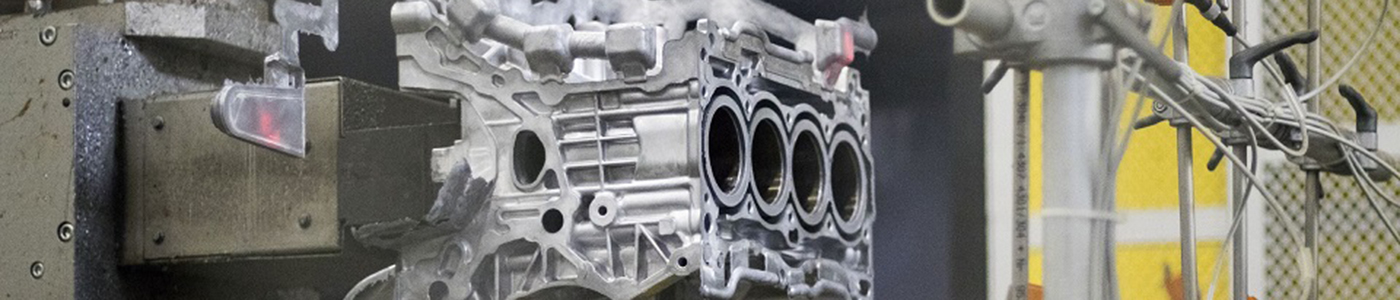

Die Casting is a casting process that injects molten metal into a metal mold (also called a mold cavity) under high pressure. Die casting is suitable for the production of large quantities of precision castings, especially metal parts such as aluminum alloys, zinc alloys, magnesium alloys, etc. with complex shapes and high precision requirements. Aluminum die casting is widely used in manufacturing due to its good mechanical properties, thermal conductivity and corrosion resistance.

MINGNON is a company that specializes in providing CNC machining services and is committed to providing customers with precision parts machining solutions. As a manufacturer with rich experience in the industry, MINGNON not only provides high-quality CNC machining services, but also provides a full range of Assembly Services to help customers assemble individual parts into complete products to ensure product performance, quality and consistency.

MINGNON offers a variety of CNC processing materials, including aluminum, stainless steel, copper, titanium alloy, ABS and nylon, suitable for aviation, automotive, electronics, electrical, medical and other industries. We perform high-precision customized processing according to customer needs to ensure that product quality and performance meet industry standards.

We can provide surface treatment services for a variety of materials, including anodizing of aluminum, polishing of stainless steel, gold plating of electroplated copper, anodizing of titanium alloy, spraying of ABS and heat treatment of nylon, etc. Through superb technology, we can improve the corrosion resistance, wear resistance and appearance quality of the materials to ensure that the products meet the highest standards.

Quality is at the heart of everything we do. We ensure accuracy and precision

at every step of the manufacturing process.

By utilizing advanced inspection equipment such as CMM, two-dimensional measuring

instruments, XRF analyzers, gauges, micrometers, and calipers, we provide you with peace

of mind and assurance that your parts are the quality you expect and demand.

Our experienced quality team applies rigorous control measures with on-site inspections

at every phase—pre-production, in-production, and final production. These inspections

focus on appearance, functionality, and specific requirements. We also provide detailed

reports as needed, including first article inspections, RoHS compliance, and visual,

dimensional, and performance assessments.

Over the past 20 years, we’ve earned multiple ISO certifications demonstrating our quality

capabilities. We guarantee timely and reliable prototyping and production services.

20+ inspection equipment

30+ quality engineers

ISO 9001:2015, ISO 13485, ISO 14001, and IATF 16949

Our advanced CNC machining technology, high-quality material processing and customized surface treatment ensure precision, durability and a product that guarantees customer satisfaction.

Please contact us with product specifications, surface treatment details, schedule and any other service requirements, we will serve you 24 hours a day.